Problems with fatigue cracking resulting from sulfidation corrosion is plaguing the Trent 1000 engines utilized by 169 Boeing 787 aircraft. Since February, there have been three “engine incidents” at All Nippon Airways, the first and most experienced operator of the Boeing 787. The first two, in February and March, were on international operations, but the most recent occurred in domestic operations between Tokyo Haneda and Miyazaki.

Rolls-Royce and ANA had a program in place to replace blades on international routes, and because of altitude and hotter running engines, felt it was unlikely to occur on domestic flights. Proven wrong in that assumption, with the same irregularities developing, ANA was forced to adopt the early replacement program to its domestic operations as well.

Over the next three years, Rolls-Royce will replace all Trent 1000 intermediate pressure turbine blades, and airlines will replace blades impacted by corrosion with new or minimally used blades in the interim. Because new blades do not pose any safety risk, ANA is comfortable in continuing operations while replacing blades on a more frequent schedule.

Rolls-Royce is, of course, offering its customers like for like replacements, and will have new blades ready by the end of the year. ANA’s program to replace blades on all 100 of its engines will take about three years to complete.

This is not the first incident for the Trent 1000 on the 787. In 2012, ANA grounded five of its 787s due to corrosion within an external gearbox on the Trent 1000 engines. That component, a gearbox from Hamilton Sundstrand, was replaced for all existing and subsequent aircraft.

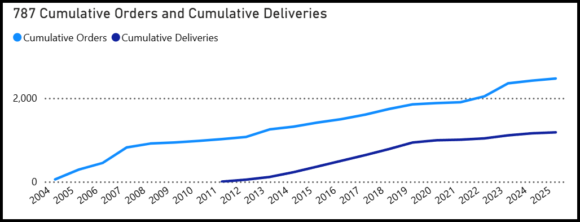

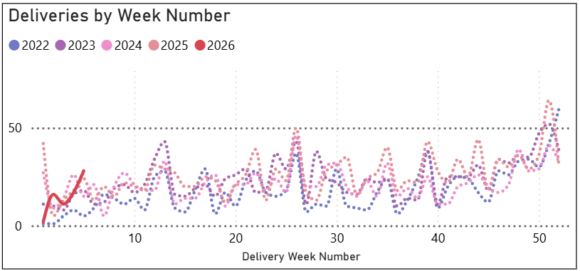

While this puts another blot against the record for the 787 program, we do not believe this will materially impact the 787 program, production rates, or orders. The problem has been identified, a solution is underway, and it is certain that Rolls-Royce or Boeing will be reimbursing airlines for the additional maintenance required for these engines.

Corrosion issues are difficult to test for when developing an engine, as corrosion accumulates over time. Once identified, however, these types of problems are typically easily resolved. Unfortunately, another item slipped through the cracks in what could only be described as a troubled development path for the 787. Just when the industry thought the 787 was out of the woods, another problem has occurred.

Views: 103