Airbus Next generation single aisle2cAirbus

The CFM RISE open rotor technology demonstrator project is steadily progressing, with GE Aerospace and Safran sharing a few updates recently. The latest came today on the sidelines of this week’s Singapore Airshow, with CFM, Airbus, and the Civil Aviation Authority of Singapore (CAAS) announcing an MoU on testing the open rotor concept in airport operations at Changi and Seletar airports in Singapore.

A lot has happened since GE Aerospace and Safran unveiled their open rotor concept, RISE, in June 2021. Over 350 tests and more than 3.000 endurance cycles have been completed on various technology bricks, individual technologies that together will form RISE.

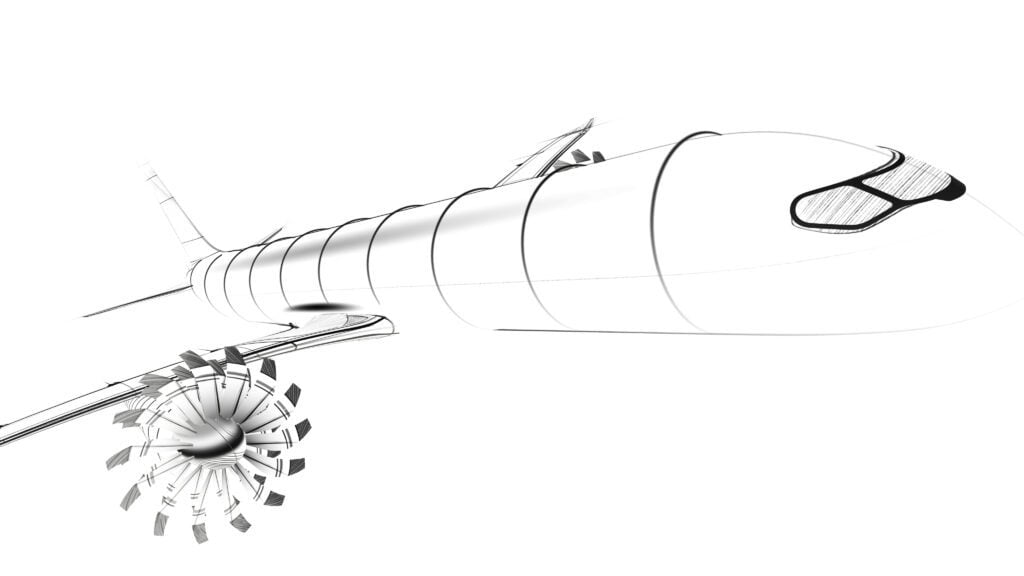

The most notable difference of this concept is the huge open rotor and a very compact core, offering a bypass ratio of 60:1 compared to 12:1 for the CFM LEAP, resulting in a 20 percent fuel burn reduction from the engine alone.

Airbus has embraced the open rotor as the preferred technology for its Next Generation Single Aisle (NGSA) aircraft, the successor to the A320neo family that should enter service in the second half of the next decade. But with its 4-meter-wide rotor, installing the open rotor on a narrowbody aircraft is a big challenge, as ground clearance must be taken into account. That’s why Airbus is not putting all its eggs in one basket but is open to ducted concepts too, notably the lower-rated version of the Rolls-Royce UltraFan, which is still in the design phase. Boeing’s approach to the open rotor has been more reserved, questioning the fuel burn benefits when installed on an airframe. GE says that fuel burn should be 20 to 25 percent better than that of a current-generation turbofan.

Demonstrator

GE Aerospace and Safran plan to flight-test the RISE demonstrator on a converted Airbus A380 previously operated by China Southern Airlines, but this will not occur until 2029. Part of the test program focuses on the impact of an open-rotor concept on ground operations at airports. That’s where the MoU with Singapore, announced at the 3rd Changi Aviation Summit on February 2, comes in.

Airbus, CFM, and the Civil Aviation Authority of Singapore said they will develop “a comprehensive readiness framework that serves as the global blueprint for airframers, airports, and airlines worldwide.” This examines how open rotors fit into existing airport operations and whether they require changes. Airports are used to handling turboprop aircraft, but with a larger rotor, safety and ground handling could differ slightly. That’s why infrastructure modifications are considered, along with current safety regulations.

Singapore will offer its expertise “to exchange technical and operational expertise across areas, including airport design, safety protocols, regulatory frameworks, and operational procedures to inform the readiness framework development.” This will all come together when the A380 RISE demonstrator will visit Changi or Seletar Airport to conduct operational trials “to test and validate the readiness framework and assess operational feasibility of this new technology.” No timeframe has been given for this, but expect this in 2029 or 2030 at the earliest.

The trials also serve another purpose, as Gaël Méheust, President & Chief Executive Officer of CFM International, highlighted. “Now, having the ability to perform a real-world demonstration, from ground handling to maintenance actions, to airport operations will give airlines and, hopefully, the flying public, confidence in the safety, durability, and efficiency of Open Fan.”

Public acceptance of the open rotor still needs to be determined. During the 2025 Airbus Summit, the airframer and GE Aerospace stressed that noise levels of an open rotor will equal those of a CFM LEAP-powered Airbus A321neo. The fuselage will require reinforcements to prevent puncture in the event of a rotor blade malfunction.

Research

At the Changi Summit, parties also announced the establishment of the Singapore Partnership for Aviation & Aerospace Research and Capability (SPAARC). They include CAAS, the Singapore Economic Development Board (EDB), GE Aerospace, and the International Centre for Aviation Innovation (ICAI).

One of the roles SPAARC wants to play is that of advanced aerodynamic research, “to support next-generation propulsion systems and enhance aircraft performance and efficiency. This includes research into novel engine designs and ensuring these advanced engines can be effectively integrated with current aircraft designs and airport infrastructure.”

Last week, GE Aerospace said it reached a milestone in the development of hybrid-electric propulsion, which will be integrated into the open rotor concept. On a testbed in Peebles (Ohio) and using a modified Passport engine, GE and NASA successfully demonstrated power transfer extraction and injection without storing energy (electricity) in batteries. This will save weight. “It’s a critical step to making hybrid electric flight a reality for commercial aviation with technologies that meet customer needs for greater efficiency, durability, and range”, said Arjan Hegeman, who is GE’s vice president of Future of Flight.

Hegeman said on LinkedIn that RISE will enter a new phase, with testing on larger module rigs to demonstrate the maturity of the new technologies. Last year, GE began dust-ingestion tests on high-pressure turbine airfoils to ensure they meet durability criteria. It is one of the lessons learned from the LEAP program, which encountered durability issues in hot, sandy environments.

Views: 25