2020 12 15 1

Boeing’s Arabian Tier 1-supplier Strata Manufacturing has delivered the first 787 vertical tailfin. The event was celebrated during a virtual presentation on December 15 from its Al Ain plant in the United Arab Emirates (UAE).

The delivery marks a new step for Strata, which has established itself as a lead supplier to Airbus, Boeing, Saab, Leonardo, and Pilatus since the company was founded in 2009 and started production in 2010. For Boeing, Strata has become a tier 1 supplier in 2011. In 2012, a contract was signed for the production of composite empennage ribs for the 777 and vertical tail fin ribs for the 787. This was followed in 2014 by a work package for empennage ribs for the 777X, with the first shipset delivered in November 2019.

The contract for the first 787 vertical tail fin (without the rudder) was announced back in 2016 at the Farnborough Airshow. Until now, Boeing has produced Dreamliner tailfins at its Auburn (Washington) plant. Strata have built a dedicated production hall called Strata Plus at its Nibras Al Ain Aerospace Park, which is a joint venture between its sole shareholder Mubadala Investment Company and Abu Dhabi Airports. Strata staff have been training at Boeing’s facilities, replicating the capabilities of the Salt Lake City assembly line at its own facilities. The company has 47 staff working of the tail fin project and plans to expand this to 75 by the end of 2022.

CEO Ismail Abdulla said that Strata is studying the introduction of robot drilling in its Al Ain plant at a later stage. The first shipset, which was actually delivered on the UAE’s National Day on December 2, will be installed on a 787 in North Charleston early in 2021. Production on another five fins has already started.

787 production rate to be reduced by half

The start of the new work package for Strata comes at a difficult time. On December 4, Boeing CFO Greg Smith confirmed that the production rate for the 787 will be reduced from mid-2021 from six to five per month as demand for long-haul jets has come down following the Covid-crisis. This compares to the current rate 10. For sure, this will have an impact on Strata’s business case on the 787, which as recently as last year still anticipated an increase to rate fourteen. Boeing also will revise the production of the 787, with the North Charleston facility becoming the sole production location from the middle of next year.

Boeing is also facing quality issues with the 787. This includes the empennage and horizontal tailplanes, with composite barrel joints showing rough inner surfaces that need rework. Boeing also discovered some deformation on both the horizontal and the vertical tailplanes which have been caused by excessive pressure during production. Inspection and rework of 787s have taken so much time that Boeing has been unable to deliver any Dreamliners in November and is unlikely to do so in December.

On December 14, the Wall Street Journal revealed more quality issues, this time involving the smoothness of composites at fuselage barrel joints. Like the issue with the empennage, the barrel problem can also result in premature structural fatigue. WSJ said a full 787 production review by the FAA is likely to happen.

Strata is aware of these issues and is dedicated to producing its parts at the highest quality levels, Abdulla said. Boeing Commercial Airplanes’ vice-president and general manager for supply chain, Elizabeth Lund, said the company has every confidence that Strata will meet the delivery schedule and produce parts to the highest quality. “This complex build for Strata was a stretch goal, but you have achieved it including complex manufacturing techniques like moldable plastic shims and on-up drilling and assembly.”

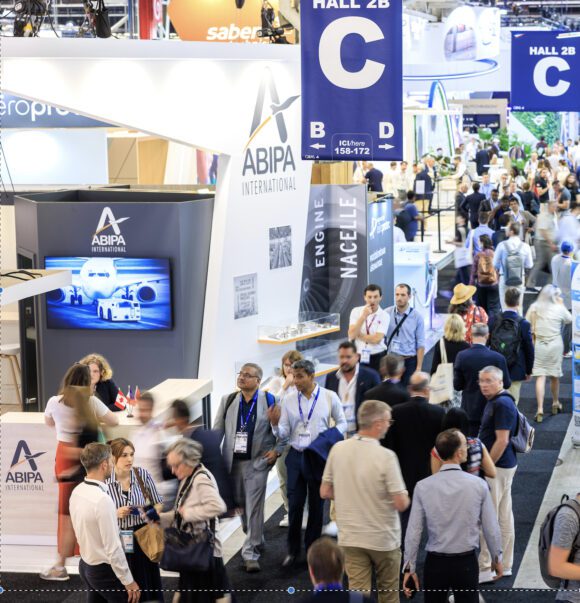

Strata Manufacturing staff with the first 787 talfin. 88 Percent of the staff is formed by females from the UAE. (Strata Manufacturing)

Strata portfolio depends on widebodies

While the 787 tail fin program is an extension of its work package with Boeing, it confirms Strata’s dependency on wide-body airliner programs. Not only does the Al Ain company makes parts for the 777 and 787, but also for the Airbus A330 (flap track fairings, ailerons, spoilers) and A350 (inboard flaps and flap support fairings). In an interview with Airinsight during the 2019 Dubai Airshow, Abdulla confirmed that Strata is looking for options to join single-aisle programs: “Recently, you have seen a softening in demand of the widebody market. It’s also part of our strategy to do higher rates and to do that you have to be on the single-aisle market. (…) We’d like to strengthen our partnership with partners in the supply chain.”

Prospects are difficult now that the industry is in trouble following the Covid crisis. The slump in demand also exposes Strata on the Boeing 777X program, for which it formed a joint venture with Belgian supplier Solvay and has built a dedicated production facility in Al Ain for the composite empennage ribs. While Boeing’s orders list still shows 309 on December 1, a number of orders will be revised (like Etihad’s and most likely the one from Emirates too), while some deliveries have been deferred.

Views: 35