2023 06 26 12.46.48

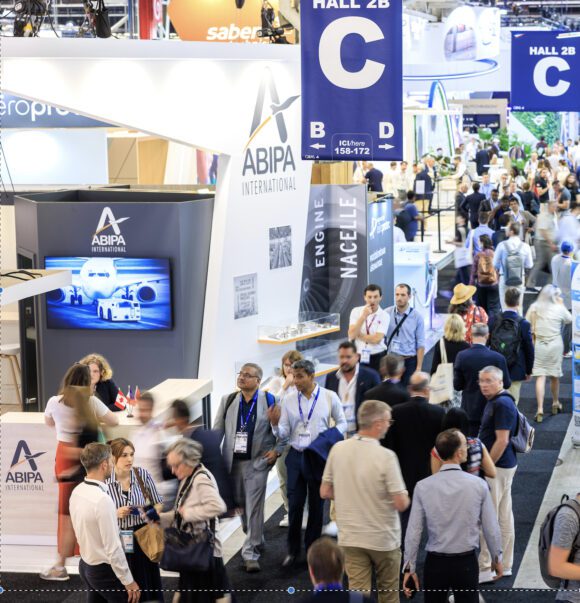

This series of stories will cover our takeaways from the Paris Air Show from a strategic perspective on the topics of Technological Change, Aftermarket and Retrofit Growth, Urban Air Mobility, SAF for Carbon Reduction, and Airbus continuing to pull ahead of Boeing in backlog and customer demand. The implications for the future of the industry are significant

We are already in an Era of Substantial Technological Change