NASAmeatball1200

Aerospace tiered supply chain no longer works for the new Urban Air Mobility (UAM) technologies, such as electric vertical takeoff and landing (eVTOL), because it is too rigid and the new entrant electric vehicle manufacturers are not including traditional aerospace manufactures in development plans.

The NASA Aeronautics Research Institute (NARI) held a Sustainable Aerospace Supply Chain and Manufacturing Workshop, Feb. 4-5, 2020, at NASA Ames Research Center. Nine keynote presentations and five panel discussions provided the breakout working groups background material for consideration in developing specific recommendations for aircraft, eVTOL, and drones. The working groups key findings for the aerospace industry included:

- Development of a new eco-systems, including an eCommerce solution to match manufacturers with suppliers

- Learning from automotive industry for manufacturing

- Understanding of importance of FAA parts certification process and requirements for traceability

- Workforce development to bring more workers into aerospace manufacturing

While the workshop focus was on the entire aerospace industry, including hypersonic, supersonic, subsonic, drones of all sizes, electric vertical takeoff and landing (eVTOL), urban air mobility (UAM), and aircraft of all sizes, the supply chain issues for drones and UAM aircraft received the most attention.

Dr. Parimal Kopardekar, known as PK, Director, NASA Aeronautics Research Institute, Aeronautics Research Mission Directorate, set the stage with a tutorial on aerospace supply chain basics. He pointed out the aerospace industry currently has more than $800Billion backlog between Airbus and Boeing, which relies on the supply chain for on-time deliveries. A supply chain and associated manufacturing requires four major considerations: 1) understanding the future needs of the aerospace industry to correctly meet demand and growth, 2) ensuring regional manufacturing hubs can transition with new capabilities to meet demands, 3) making sure that academic curriculum will cultivate applicable talent and skills for the workforce, and 4) encouraging entrepreneurship and businesses of all sizes to meet national needs.

For the UAM market, PK provided five recommendations:

- Supply chain planning needs to start with vehicle development

- Industry needs to start building an entire new supply chain eco-system to meet needs of new technologies

- Aerospace can learn from other manufacturing industries, such as auto

- Educate traditional aerospace suppliers to consider electric vehicles

- Expose regional manufacturers and industry supply chain associations to the emerging needs of electric aircraft

Mike Hirschberg, Executive Director the Vertical Flight Society, provided an overview of the emerging eVTOL market and identified five challenges:

- Technology: batteries, motors, etc. for larger sizes, e.g. pilot + 4 pax

- Infrastructure: ground and air space

- Flight operations: Pilot shortage vs. autonomy

- Standards & regulations: to meet FAA certification

- Public acceptance: safety, noise, NIMBY

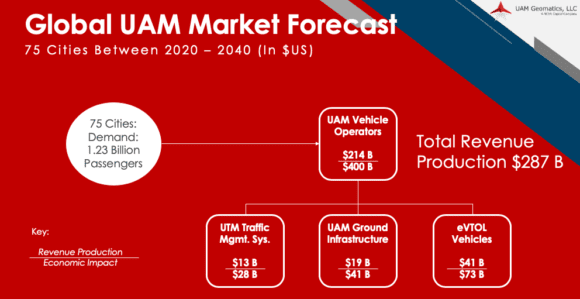

NEXA Advisors quantified four (4) distinct supply chains for UAM at $287B over the next 20 years to support 1.23B passenger trips. The four supply chains include:

- eVTOL/UAM Certified Vehicle Operators

- UAM Ground Infrastructure

- UTM Infrastructure

- eVTOL/UAM Vehicle Manufacturers

US Department of Homeland Security and Department of Defense emphasized that a strong and resilient aerospace supply chain and manufacturing base is key to U.S. competitiveness and national security. An aerospace supply chain network is unique due to needs related to aviation safety, national security, and criticality of operations.

FAA provided a tutorial on parts manufacturing approval (PMA) for production certification and the importance of ensuring parts traceability.

In conclusion, to minimize delays and backlog in larger aircraft deliveries as well as meet the demand of maturing, domestic small- and medium-size unmanned aircraft systems and well-funded flying taxi-type companies, availability of parts and systems is essential. A new eco-system needs to be developed to ensure the aerospace industry continues to be a significant economic driver for the U.S.

Views: 1