KLM Shell synthetic SAF

You have sustainable aviation fuels (SAFs) from waste cooking oil, green feedstock, or even household waste. But at a European conference on February 8 in The Hague (The Netherlands), two new initiatives were announced that specifically target the aviation industry: SAFs extracted from carbon dioxide in the air and SAF from green hydrogen and CO2.

With rising public pressure on the aviation sector to deliver on its promises of more sustainability, there have been numerous initiatives to reduce the industry’s addiction to oil and kerosene. Hybrid-electric, full electric, and hydrogen technology look all promising energy sources for future airliner concepts, but their entry into service onto commercial airliners is still years away. That’s why the use of SAFs is a solution.

Last month, European airlines and NGO’s issued a consensus statement that called for a stepped approach for the introduction of SAF. In the first phase until 2025, they recommend the use of waste oils as the primary source. Once the availability of waste oils has reached its limits, refer to lignocellulosic residues and wastes such as the biogenic fraction of municipal solid waste (MSW), agricultural residues & forestry residues. In phase 3, electrofuel could be a source for SAFs.

Two new initiatives

The two electrofuel initiatives revealed on February 8 add a new dimension to SAFs. The first is called Zenid. It is a consortium from Zurich-based Climeworks, Amsterdam-based SAF-specialist SkyNRG, Dusseldorf-based power generator supplier Uniper, Rotterdam The Hague Innovation Airport, and Rotterdam The Hague Airport/Royal Schiphol Group. They announced two memoranda of understandings to construct a demonstration plant sized between 5.000 and 10.000 square meters in Rotterdam, that will capture CO2 directly from the air and use locally supplied renewable energy to run on. The plant will initially produce 1.000 liters of SAF per day, growing this to 4.000 liters at a later stage.

The exact location has to be confirmed after the outcome of a 2019 feasibility study into the technology has been checked and updated. Zenid also has to source funding but hopes to start production in 2023.

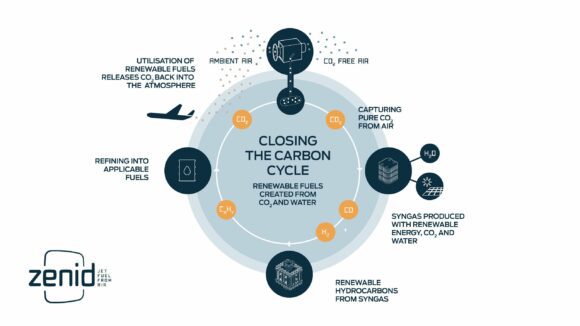

This sounds like magic, but the feasibility study confirmed it should be actually a lot easier. Huge modular filtering machines extract CO2 from the air. After co-electrolysis, the CO2 and collected water from a synthetic gas or syngas in a Fischer-Tropsch reactor is transformed into liquid hydrocarbons. After the refinery, the oil becomes Jet A1 aviation fuel that can be directly used on aircraft. As it captures and re-uses CO2, Zenid claims to be fully carbon-neutral. Using SAFs, engine emissions will have hardly any nitrogen oxides or particles and no sulfur from aromatics and contain much less water.

KLM scoop: first commercial service with synthetic SAFs

That the use of SAFs from CO2 is already a reality, was confirmed during the conference. Shell and KLM announced that 500 liters of synthetic kerosene based on CO2, water, and renewable energy had been used on a flight from Amsterdam to Madrid on January 22 on a Boeing 737-800. They claim it to have been the first commercial flight using synthetic fuels in history, albeit at a very modest level. “It is an important first step and together with our partners we now need to scale up, accelerate and make it commercially viable”, Shell CEO Marjan van Loon said.

With the engineering expertise from Uniper, Climeworks will now take the next steps before actually start constructing the demonstration plant. No specific date was given when this should be up and running. Climeworks already has fourteen air capture facilities and claims that out of each 100 tons of CO2 captured, 90 tons are permanently removed from the air and only 10 percent is re-emitted. The company announced last January that Microsoft has selected Climeworks to reduce its carbon footprint.

Synkero also uses CO2

Another project launched today is Synkero, a Dutch start-up that partners with SkyNRG, KLM, Royal Schiphol Group, and Port of Amsterdam. It plans to complete a SAF plant in the Amsterdam area in 2027. As a source, it uses CO2 from industrial processes that are unavoidable or directly from the air, like Zenid. Using green hydrogen produced with sustainable energy sources from wind and the sun, Synkero too uses a chemical process to convert hydrocarbons into synthetic SAF. Situated at the port of Amsterdam, Synkero can directly tap into the existing fuel system that runs from there to Amsterdam Schiphol Airport.

Current regulations forbid the use of 100 percent SAFs on commercial flights, so they have to be blended 50/50 with conventional kerosene. However, this is likely to change in the coming years as more and more SAFs are used. In January, Boeing said it is committed to certifying its aircraft to 100 percent SAFs by 2030, having used them on various flights of its 777F ecoDemonstrator in 2018. “Sustainable aviation fuels are proven, used every day, and have the most immediate and greatest potential to reduce carbon emissions in the near and long term when we work together as an industry“, said Chris Raymond, Boeing’s Chief Sustainability Officer.

The Boeing 777F ecodemonstrator used 100 percent SAF on various test flights in 2018. (Boeing)

Both Synkero and Zenid are positive their projects will succeed and contribute to the change of aviation. “Making aviation more sustainable is still in its infancy, but an enormous acceleration is now taking place”, Synkero says on its website. “Realizing such an energy transition will take time, there is no quick fix. Usage of SAF will generate CO2 reduction within the aviation sector, in contrast to offsetting schemes.”

Climeworks’ co-founder Christoph Gebald says: “The launch of Zenid shows the commitment of the industry towards fully circular fuels from air and their role to substantially reduce aviation’s CO2 emissions.” But to become a significant player in the aviation industry, eventually, Zenid will need to produce millions of synthetic fuels. The availability of sufficient green energy to produce them is conditional to their success, otherwise, the positive effects of SAFs are completely negated the negative ones.

Price is another factor, says Zenid. Synthetic fuels are expected to be produced at EUR 1-2 per liter, which is more than traditional kerosene. In order to make them competitive, incentive schemes, the mandatory blending of SAFs, or the introduction of taxes on carbon fuel should be imposed on a European or worldwide scale. While Zenid could produce SAFs for other transportation modes too, but the company prefers to focus on the aviation industry as it sees the biggest gains in carbon dioxide reduction are to be made here.

Seven EU countries support accelerated development of SAFs

As a frontrunner for SAFs, the Dutch government is pushing its European counterparts to have airlines entirely fly on sustainable fuels in 2050. During the conference, this received support from other EU member states. The Netherlands, France, Sweden, Germany, Finland, Luxembourg, and Spain indicated in a joint statement that recovery from the current crisis due to the pandemic must go hand in hand with accelerating the sustainability of the aviation sector in order to achieve climate goals and call on the European Commission to come up with a European blending obligation. “The Member States view the development of sustainable synthetic kerosene in addition to sustainable biokerosene as one of the most promising and effective ways to reduce aviation emissions in the coming decades.”

Views: 2