These are confusing times for commercial aerospace companies. With the change in administrations in Washington, DC, uncertainty has increased for industry participants amidst discussions of tariffs, new manufacturing facilities, potential certification exemptions, and regulatory policies. Planning is complex when you don’t know the new rules or their potential impacts. Let’s look at some of the issues industry participants are taking.

Tariffs

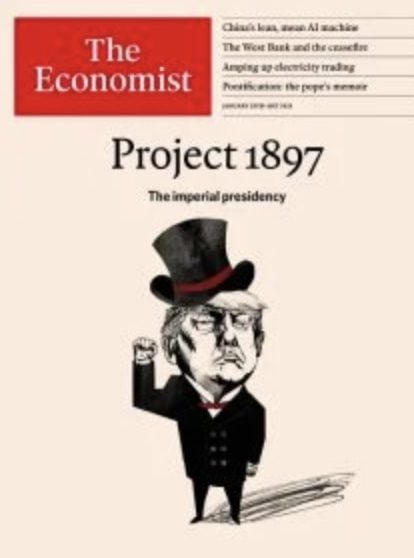

The Trump administration has proposed tariffs on Mexico and Canada, increased tariffs on China, and new reciprocal tariffs on other countries that restrict US goods. While the implementation of Mexican and Canadian tariffs has been postponed by a month, that has added to the confusion as we try to understand whether or when those tariffs may be implemented.

Could this impact foreign direct investment by US companies internationally? While the Trump administration would prefer US jobs, realistically, some US companies may need to invest internationally to remain competitive in some markets. Conversely, could it lead to an increase in foreign companies investing in the United States? The complexity of international aerospace can quickly be confusing as policies change.

Airbus’s multi-national aircraft production strategy may benefit the company, as it currently has final assembly facilities in Mobile, Alabama, Tianjin, China, and its European facilities in Toulouse, France, and Hamburg, Germany. With a manufacturing facility in the United States, the company would likely not be exposed to tariffs for the popular narrow-body aircraft built here. But would that apply to wide-body aircraft built in France? Would the international supply chain face constraints from imported parts built elsewhere? How far would tariffs apply to a complex global supply chain that could result in more harm to US companies manufacturing companies that are exported globally? Boeing builds aircraft only in the US. Would retaliatory tariffs impact Boeing negatively or positively?

Bombardier, a Canadian company, indicated in its quarterly financial report that it could not provide financial guidance for 2025 because of the threat of tariffs. Of course, this is despite strong US content on the aircraft, built using the same multinational supply chain companies that also supply US-built jets. Bombardier recently opened new maintenance facilities in the US to capture aftermarket revenues and should be able to avoid tariffs on services rendered in the United States. At least, we think so at this point, but the devil lies in the details.

What about CFM International, which makes the LEAP one of the most popular commercial aircraft engines in the world, powering aircraft from Airbus, Boeing, and China’s COMAC? A 50/50 joint venture between GE and Safran, is it a US or French company, or neither? We do not know how the new administration will categorize this extremely successful multinational enterprise.

The bottom line is confusion. We don’t know where tariffs will be applied or whether traditional industry supply chain relationships can survive if tariffs suddenly increase costs. Politics, rather than product quality, efficiency, support, and pricing, may soon determine who wins or loses.

Foreign Direct Investment

Boeing, the largest exporter in the US, also faces significant challenges globally. Its major competitor, Airbus, has a manufacturing facility in China. Boeing has been contemplating a manufacturing facility in India, which has grown in importance as an export market, and is seeking additional local manufacturing jobs.

Several headlines recently discussed that possibility. Indian Prime Minister Modi, who celebrated opening a major Boeing engineering facility last year, is hopeful of attracting a final assembly line in India. Recently, Boeing threw cold water on that prospect, and statements at the Aero India show indicated that more orders from India would be needed. Forecasts call for India to surpass China and the United States to become the single-largest commercial aircraft market by 2050.

While Boeing may not be able to agree to a new final assembly facility today, it needs to consider its international footprint and how it will serve South Asia, which will become the largest region in the global airline industry.

Interestingly, Air India has voted with its pocketbook. They executed options for 85 additional aircraft from Airbus but have declined to execute a similar number of options for new Boeing aircraft negotiated at the same time as the competitor’s order. If customers vote in their economic interests, that could negatively impact US companies. Will building aircraft in the US be an advantage or disadvantage? It isn’t clear under normal circumstances, especially with a US President who likes to float radical ideas publicly. Unfortunately, sometimes, those ideas seem “half-baked” rather than thoroughly evaluated.

Exemptions and Regulatory Policies

Boeing, in particular, is currently the subject of increased regulatory certainty. The FAA has capped 737 production to 38 monthly units until the agency is assured that the company can successfully build and deliver additional aircraft. While Boeing and the FAA have agreed upon key performance indicators to guide that transition, raising that rate is not a given and will be evaluated based on complex numbers.

On the certification front, Boeing has been forced to request an additional exemption on the 737 MAX 7 and MAX 10 models from the existing certification regulations related to the yaw damper system. Granting that exemption would result in the models being approved before the components and guiding software can meet the most recent certification requirements, which would be retrofitted to all aircraft at a future date. The possibility that aircraft might be delayed adds to the confusing process of fleet planning, and the “what if” scenarios need to be evaluated just in case aircraft are further delayed.

Boeing has historically received several exemptions to new certification rules, including one for a requirement for stronger engine nacelles to contain a catastrophic engine failure. It turns out that the engine anti-icing system, if left on during a flight, could weaken the nacelle (engine covering) that could shatter during an engine failure and allow shrapnel to penetrate the fuselage, potentially causing an explosive decompression at altitude. This requirement follows a similar incident on an earlier 737 model that caused the death of a passenger on Southwest Airlines after an engine nacelle separated from the engine during a catastrophic engine failure.

If Boeing obtains the just-requested exemption, it could likely certify the aircraft in 2025. Without the exemption, the aircraft could take an additional 18-24 months to approve, causing further delayed deliveries to airlines and high additional costs for Boeing. If you are Southwest Airlines waiting for the 737 MAX 7, this is confusing and fraught with financial risk.

Which way will the new administration rule? While Mr. Trump is an existing Boeing customer and owns a Boeing 757, he is also unhappy that the Air Force One replacement program is running years late, as the most recent schedule update shows the new aircraft would enter service after his term had ended. Mr. Trump called Boeing’s performance unacceptable and discussed that issue with CEO Kelly Ortberg. The one thing that isn’t confusing is that he wants his new airplanes sooner rather than later.

With the FAA and the executive branch holding sway over the key factors impacting Boeing’s cash flow for the next few years, how will a transaction-oriented President influence the agency’s relationship with Boeing? Will the FAA go easier on Boeing to ensure that the US pumps out airplanes and an improved balance of trade, or will not meeting deadlines for Air Force One come back to haunt the company if its requests are denied and certification is delayed.

There will likely be a negotiated quid-pro-quo, but we don’t know what that deal will look like or what it will mean for aviation safety and regulatory policy. Confusing.

The Bottom Line

It is difficult for us to predict where the industry is headed when key decisions in Washington could fundamentally impact the competitiveness of key players and the balance of trade. We have no idea how Trump 2.0 will evolve, and we only hope that rationality and transparency will emerge with enough time to mitigate confusion and better plan for new policies. While we’d love to bet everything will be rosy, we can’t do that without more information.

Unpredictability may provide an advantage in negotiations but can lead to overreaction and decisions. What we need today is clarity—who, where, what, when, and how. At least then, we’d know how to mitigate negative consequences. Mr. President, our industry could use more transparency and a less confusing discourse on policy initiatives.

Views: 89