2019 06 10 22 09 33

News

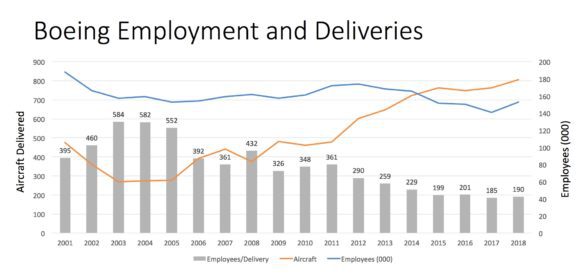

Boeing over the last few years has continued to increase aircraft production while slightly reducing its work force, providing a labor productivity improvement for the company. When we look at this over a longer term, back to 2001, the results are startling.

Aircraft delivered have increased steadily over the period after a drop in the post 9-11 years, while employment has dropped from prior levels. As a result, the number of employees per aircraft has dropped substantially as well over the period.

Analysis

Automation of processes and outsourcing of some systems formerly completed at Boeing could explain some of the productivity gain. But if we looked at a Boeing plant thirty years ago versus one today, the immediate reaction would be where did all the people go? Aircraft manufacturing has certainly become more productive and competitive, and Airbus leaped ahead of Boeing in the 1990s with few people on their final assembly line when compared with Boeing’s productivity in the old days.

Moving from over 500 employees per aircraft to less than 200 is a tremendous productivity gain over the a 17 year period. Boeing has done a superb job in streamlining its operations and production facilities.

We don’t have a breakdown of the number of production workers versus the number of engineers at Boeing, but suspect that they are fairly close these days. Engineering talent is critical to new product development, and this is an area that has let Boeing down during the same period.

The 787 was late, and later grounded. The 737 MAX is currently grounded after two accidents. The 777-9 is now taking its second program delay. Each of the company’s three commercial aircraft families for the future has taken a hit in recent years. One of the question that could be asked is whether the employee cuts were over-aggressive on the engineering side given the complexities of new technologies?

Insight

Productivity can be defined as output over input, and Boeing has nearly doubled its output of aircraft from 2001-2008 while reducing overall employment levels by 18%. That is a phenomenal achievement. But did it go too far?

When the problems of program delays, groundings, and delays for customers that result in penalties and payments are considered, has Boeing really done as well as the productivity numbers show? Unfortunately, the answer is no. The 787 overruns and grounding have made the program break-even at best, the 737 MAX grounding is generating substantial costs and concerns, and the 777-9 delays will likely cost the company payments to its launch customers for missing their target.

Could additional engineers have made a difference in the three major development programs and held down costs? While we don’t know the answer, the old adage that an once of prevention is worth a pound of cure may apply in this situation.

Views: 25