2020 07 19 6

In ten years’ time from now at the Farnborough or Paris Airshows, a new kind of commercial aircraft will most likely be showcased: the hydrogen airliner. At first the size of a regional jet but possibly as a short-haul aircraft too that could be successors to the current Airbus A320neo-family and Boeing MAX generation. Hydrogen is the way to go for aviation.

If a crystal ball exists, this is something a recent European study from Clean Sky 2 and the Fuel Cells & Hydrogen 2 Joint Undertakings wishes to become reality around 2030-2035. The study provides a clear roadmap for hydrogen technology to become the alternative to kerosene-based aviation. Participants in the study include Airbus, Boeing, German research agency DLR, Bauhaus Luftfahrt, Ariane Space, GKN Aerospace, BP, Air Liquide, Hydrogenics, Safran, but also airports like Schiphol, Liege as well as easyjet as the sole airline in the mix.

The benefits of hydrogen over fossil-based fuels are obvious: no carbon dioxide emissions. That’s the plan behind the 2015 Paris agreement that covers environmental targets for 2050, the European Commission’s recent Green Deal, the Air Transport Aviation Group (ATAG) target of 50 percent CO2-reduction by 2050, and the ICAO/IATA – albeit much-criticized – Corsia reduction scheme.

If the aviation and airline industry wants to meet these targets in 2050, they have to act soon and start developing hydrogen technology. Forget the earlier attempts, like Russia’s Tupolev TU-155 that first flew in 1988 of the Deutsche Airbus Cryoplane, an A310-based demonstrator presented in 2000 that never was. The next decade needs to be fully exploited to mature this disruptive technology, the study says. And there is a golden opportunity to grasp: 2035 is the year when the next generation of medium-range commercial airliners needs to be ready. Work to be done then.

Bulky tanks need to be slimmed down

Which is easier said than done. As the Clean Sky 2 and FCH 2 JU study explains, hydrogen has specific characteristics that define its use. It can be stored as a gas (H2) but this requires big and bulky tanks. Cryoplane had them on top of the fuselage, creating a Beluga lookalike aircraft. Better use hydrogen in its liquid (LH2) form but even then storage within an airframe remains a challenge.

It can be used as fuel to burn in H2-powered engines (hydrogen turbines) or feed fuel cells (hydrogen fuel cells) that convert hydrogen and oxygen into electricity to power electric engines. The former variant would reduce climate impact in flight by 50-75 percent, the latter by 75-90 percent compared to current kerosene technology.

Both variants will emit 150 percent more water vapor but contrails are heavier and optically thinner and their effect on global warming will be briefer. NOx-emissions will be 50-80 percent lower compared to kerosene powerplants.

A major topic of further studies will be how to integrate hydrogen within the aircraft design. Current hydrogen tanks are about four times as big as kerosene tanks and require active cryogenic cooling at -252 degrees Celsius that include all pipes. The study concludes that tank mass must be reduced by 50 percent to 12 kWh/kilogram or create a so-called gravimetric index of 35 percent (weight tank versus weight LH2) if the concept will be successful.

Hydrogen will not be stored in the wings but in tanks aft of the passenger cabin. As a result, airframe length will have to increase and as a consequence aircraft weight. This will determine range and efficiency, although cryogenic cooling will increase engine efficiency by 40-50 percent compared to conventional engines.

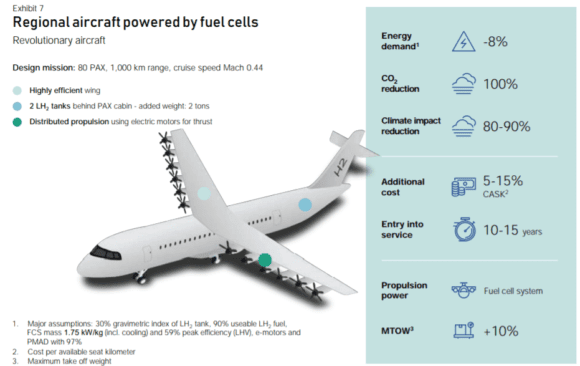

Initially, LH2 will be suited best on three types of aircraft: commuter aircraft with up to 19 passengers, 20-80 seat regional airliners, and 81-165 short-range airliners. For these three, the range shouldn’t be an obstacle.

The commuter and regional aircraft will use hydrogen fuel cell technology and electric propulsion, with a number of small electromotors positioned on a high-efficient wing’s leading edge. The former would have a range of 500 kilometers, the latter 1.000 kilometers. Two hydrogen fuel tanks are to be positioned behind the cabin, adding 0.5 tons in weight to the commuter aircraft and two tons to the regional airliner.

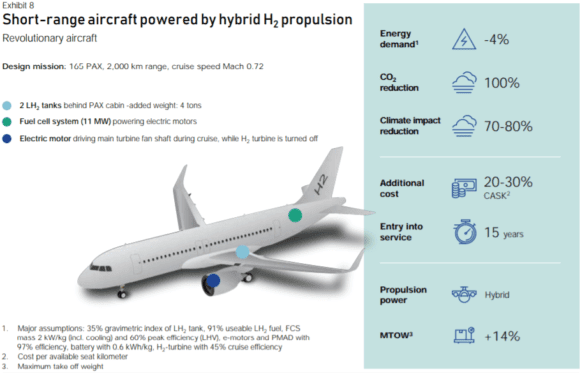

The short-range airliner could look like an A320/MAX and have two LH2 tanks behind the cabin, adding four tons of weight. Hydrogen would be used for fuel cells, which powers electric engines positioned like conventional turbofans under the wings.

Hydrogen jets more expensive to operate

Operating these hydrogen airliners is more expensive than current-technology aircraft: 25-30 percent or USD 4.5 cents per available seat kilometer compared to USD 3.6 cents for a state-of-the-art kerosene version. Part of this is a higher Capex (plus seven percent) thanks to the more expensive tank infrastructure, but also higher are fuel costs (nine percent), maintenance costs of the tank infrastructure (six percent), while longer refueling times and reduced flight cycles cost another three percent. A hydrogen aircraft is expected to do seven percent fewer flight cycles per year.

The study also calculates abatement costs, which will be $40-80 per ton of carbon dioxide for the commuter aircraft, $90-135 for the regional aircraft, $170-250 for the short-haul aircraft, $200-300 for the medium-range version, and $280-420 for the long-haul version.

This is just the short-range version. Developing bigger hydrogen-powered airliners will require more time until 2035-2040 even if an evolutionary approach is taken to let’s say an A350-like aircraft. A 250-seater with a 7.000-kilometer range would require two hydrogen tanks, one forward and the other aft of the passenger cabin but of an even more compact size. The fuselage would have to be extended by ten meters, adding 29 tons of weight. Compare this to an A350-1000 with only the seat capacity of a -900. Propulsion would be by hydrogen turbines. Operating costs would be 30-40 percent higher compared to a conventional jet.

A 325-seater with a 10.000-kilometer range is some 20 to 25 years away from now. It would need a 30 percent longer fuselage to incorporate two tanks, adding 52 tons of weight. Hydrogen turbines are the only realistic power option as fuel cell technology would be too heavy on an aircraft this size.

Another step in tank technology would improve energy demand by 15-25 percent, possibly moving towards a blended wing aircraft design. Operating costs would be 40-50 percent higher compared to today’s airliners. The climate impact of these bigger jets would be reduced by 40 to 60 percent.

ZeroAvia already has flown a hydrogen prototype

While the Russians have gained experience with hydrogen some 32 years ago, more recent tests have started on a commuter-size aircraft owned by ZeroAvia. The US and UK-based company started its HiFlyer project only in early 2019. On June 23 this year, its Piper M-class six-seater with hydrogen fuel cell technology became the first electric-powered flight of a commercial-scale aircraft in the UK. On September 25, the Piper did its first hydrogen-electric flight.

Beyond HiFlyer, ZeroAvia plans to develop a 10-20 seater with a 900-kilometer range within the next three years, followed by a 50-100 seater round 2030. ZeroAvia thinks developing a 200-seater with a 5.550-kilometer range by 2040 is possible without breakthrough technology.

Infrastructure is another hurdle to take

Building the hydrogen airliner doesn’t stop here. Clean Sky and FCH 2 JU stress that the infrastructure to produce sufficient hydrogen needs to be in place first before the airline industry can consider operating such aircraft. If LH2-powered aircraft are deployed where they are the most useful, the study thinks some forty percent of the fleet will be hydrogen-powered in 2050.

This would require forty million tons of hydrogen via a proper and safe refueling infrastructure, which needs double the number of fueling trucks compared to kerosene as hydrant systems are too expensive. At airports, ground handling and operations will have to be adapted to the different fuels, which takes double the time to refuel. Producing the clean stuff only makes sense if renewable sources of energy are needed in order not to waste any benefits beforehand.

The report recommends following a specific roadmap which includes an R&D path for the development of key components (tanks, fuel cells, turbines), aircraft designs, the hydrogen production infrastructure, and the regulatory framework.

While this might look like a couple of huge steps to take, the future might not look that far away as it seems. The European Commission has put its full weight behind hydrogen and on July 8 launched the European Clean Hydrogen Alliance with the aim of producing at least forty Gigawatts of renewable hydrogen electrolyzers by 2030. The EC has called on stakeholders to join the alliance.

The initiative has been welcomed by Airbus. “We welcome the EU Hydrogen Strategy and Roadmap released today. We, at Airbus, are committed to developing sustainable flight and believe hydrogen is one of the most viable solutions,” CEO Guillaume Faury said the same day on Twitter.

While Airbus is actively promoting the use of sustainable aviation/biofuels which can help reduce the carbon footprint and has studied electric propulsion together with Rolls-Royce and Siemens under the by now canceled E Fan-X program, Faury seems to be looking further ahead. In recent interviews, he said Airbus will invest in the development of a carbon-neutral aircraft that should be available around 2035.

“Urgent need to act now”

Hydrogen is the way to go for aviation, Clean Sky says. But the report concludes: “There is an urgent need to act now. Depending on the size of the aircraft the introduction of larger new aircraft typically takes around 15 to 20 years, and broad deployment across the fleet another 10 years. (…) This opens a window of opportunity between 2030 and 2035 for a new, decarbonized aircraft in this segment. The next generation in this segment would then be expected only between 2045 and 2050 which would be too late to achieve the decarbonization objectives for this segment set by the EU and ATAG targets.”

It adds: “The sector roadmap needs to set clear ambitions, align standards, coordinate infrastructure build-up, overcome market failures, and encourage first movers. An inspiring mid-term target could be, for example, the introduction of an H2 -powered short-range aircraft before 2035. The long-term policy framework should lay out the rail guards for the sector, including how climate impact will be measured and the roadmap will be implemented. The European Union could first target commuter, regional, and short-range flights as they are covered within its jurisdiction, and then expand this to medium- and long-range aircraft together with its international partners.”

Views: 64

keep up the good work!!

Exciting times! Can’t wait to see the developments over the next few decades.

Very good and informative article. The third era of aviation has just begun.

Good informative article describing the enormous challenges for a worthwhile goal.

Isn’t hydrogen highly explosive, and very hard to store in its gaseous form? To keep hydrogen liquid, doesn’t it have to be stored at -459°F?

Sounds dangerous and highly complicated.

It’s liquid hydrogen we are talking here that indeed needs storage at cryogenic temperature. It’s a challenge, but Airbus is confident it can master the technology using the experience from the space launcher industry.