BAE Systems just announced they are considering working towards the possible launch of a passenger-to- freighter conversion program for the Avro RJ jetliner and is seeking customer feedback to help assess market potential.

BAE says building on the experience gained and in-service success of the BAe 146QT (Quiet Trader) freighter, of which around 30 aircraft were produced, they spent the past year assessing the suitability of the newer-build Avro RJ as a freighter. This work has created a full OEM-designed specification for the freighter which is now being offered to the market. The principal variant for conversion would be the RJ100 aircraft which are now starting to come out of passenger service and will be available over the next few years.

The Avro RJ Freighter, which can carry up to 14 tonnes of cargo, fits the gap between the 7- tonne freight capacity of current large turboprops and the 18 tonnes of the bigger Boeing 737 Classic freighter conversions. Typically the RJ100 can be bought for between $1.5m and the freighter kit and conversion would cost between $2.2 and 2.8m. Availability would be from the end of 2017.

BAE offered this useful Q&A

Will the RJ Freighter use the same freight door as for the BAe 146QT?

The door is identical to the 146QT – we will take the opportunity of upgrading the actuation system with modern kit. The surround structure will require minor modification to accommodate a slightly different build standard on the RJ100.

How long have you spent on assessing the suitability of the RJ for freighter conversion? How many design hours? How much have you spent?

The business has spent around 12 months assessing the feasibility of the RJ freighter and coming up with an industrialisation plan. Around 3500 man-hours have been spent to date.

Is there that much difference in fact between the two aircraft?

To the untrained eye there would appear to be very little difference between the 146 and the RJ however the RJ has uprated engines offering better economics and improved aircraft performance, a glass cockpit and is cleared to a higher ceiling offering the attendant operational benefits (RVSM and CAT 3 performance).

How many modifications will be required for the RJ Freighter to cater for the differences between the BAe 146 and RJ?

We would anticipate that the structural modifications are relatively minor in nature.

How is it that you can fit up to 14 tonnes into the RJ100 Freighter and yet the dimensionally similar BAe 146-300QT was only able to carry up to 12.5 tonnes?

The volume is the same; however the candidate aircraft is cleared to carry a higher payload as a result of continuous product development over the years.

What has the operator base told you so far about what they want in terms of an RJ Freighter? More range? More payload?

The feedback has been positive – the speed advantage (compared with a turboprop) allows improved utilisation/scheduling and through the night operation from a noise restriction perspective. The steep approach and CAT 3 clearances combined with the STOL performance clearly offers significant operational benefits.

If you need extra range how will that be achieved?

BAE SYSTEMS are currently investigating the addition of a modular underfloor fuel tank system which can offer up to an additional 1000NM range potential.

Do you foresee a demand also for the smaller RJ85 as a freighter, particularly for unpaved runways operations?

There is no reason why the RJ85 cannot be developed as a freighter using the kit which will be applied to the RJ100. The RJ85 is cleared for unpaved runway operations hence an RJ freighter would be ideally suited for life line /humanitarian use.

Can you state who your strategic MRO partner will be and in what timescale you will start to cut metal?

We have not formally contracted with any one specific MRO partner for this activity however the discussions we have had to date would lead us to believe that teaming with an MRO partner is not going to be an issue. We are keen to launch the programme in the near future subject to customer demand.

Where will the conversions take place?

We would aim to have the initial conversions performed at Prestwick where our engineering team reside. We believe that having our engineers in close proximity to the conversions lends itself to minimising the associated risk.Post this we are happy to support our Customers wishes in terms of where the follow on conversions will take place.

Who will build the Large Freight Door and who will supply the roller floor? If the door is the same as the BAe 146QT can you still use the tooling for that? Will Aviaone Craiova in Romania – who built the LFD for the pax to freighter conversion programme instigated by the Asset Management business several ago – build the door?

The manufacture of the door and surround structure will most likely be sourced in the U.K – a significant proportion of the tooling has been repatriated from the conversion centre in Romania where a similar exercise on the 146 took place several years ago.

What makes you think that the RJ Freighter conversion will be any more successful than the ill-fated BAe 146QT pax to freighter programme instigated by Asset Management several years ago and which led to only two aircraft being converted – one of which has never been sold?

Clearly we would seek to incorporate all the learning from the Romanian experience. Fundamentally it really comes down to price – the cost of the asset and the cost of the conversion – A good quality RJ100 can be picked up for between $1m – $1.5m , that’s a lot of aircraft for the money. If we can launch the programme with an order book of 10 or more aircraft then we can start to generate economies of scale in terms of kit manufacture and learning thus keeping the conversion costs to a minimum.

Presumably you will need a proof of concept aircraft. Have you identified a source to provide such an aircraft?

We have had several offers of aircraft for the proof of concept demonstrator; this is not regarded as a showstopper.

Who will you work with to source multiple aircraft for possible conversions?

There are 3 or 4 operators and lessors showing positive interest in the project – clearly they will need to be assured that we have a price and conversion programme which “works” for them and this will be the next phase of business prior to building an order book.

Where is the funding coming from to support this venture? Will it be internally funded? How much will you need to go ahead?

To date approximately 3500 man hours have been spent by BAE SYSTEMS Regional Aircraft on developing the programme which we are now taking to the market. It is not our intention to fund the programme beyond what already has been committed. We would require interested parties to commit to the programme by way of non refundable deposits to initiate a full industrial programme.

Do you need a minimum number of firm commitments before progressing to a firm launch? How many?

The programme will not be launched unless firm commitments are in place. We would anticipate a minimum of 10 conversions to make the programme viable.

When do you anticipate making a go/no-go decision?

Time is of the essence as aircraft are being retired as operators re-equip. We would wish to have the first conversion completed in Q4 2017 and anticipate the first aircraft would take through the programme in around 9 months. Working back from these dates we would anticipate a go/no go decision circa November 16.

How do you propose to compete with the economics of the bigger B737 Classic freighter conversions? Presumably the acquisition costs are not much different but the payloads and ranges are much better and the aircraft are presumably still competitive carrying smaller payloads?

The 737 freighter is circa $5M – we would anticipate the converted RJ100 freighter to be significantly cheaper.

Where do you foresee market demand being strong for the RJ Freighter? Is Africa a potential market?

The RJ is an ideal solution for airline start ups and those who are growing their operation from props to Jets. The STOL characteristics and unsealed and narrow runway performance generally would certainly suit remote operations in mining and humanitarian relief roles.

What prospects do you see for other freighter applications such as Combis? Is Canada a market potential?

Developing a combi would be a natural extension to this programme should there be a demand. The Canadian market is certainly well suited to the RJ and, with additional fuel tank capacity, would eliminate the need to refuel at remote outstations which can be cost prohibitive.

How many BAe 146QTs remain in service to date?

There are 15 BAE 146 QT aircraft with Pan Air, Cobham, Corporate Air Travel and Pion Air.

How many aircraft are still active in the fleet?

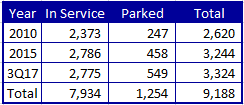

89 BAe 146 aircraft and 131 Avro RJs are still in active operation.

Views: 14

I would like to find if there were any kits ever made and if they are available as we speak.

What’s the lead time if one makes a request now?