IMG 3080 scaled

General Electric (GE Aerospace) has reached an important technical milestone with the hybrid-electric power system that is part of its zero emissions roadmap. It successfully ran tests at NASA’s Electric Aircraft Testbed (NEAT) in Sandusky (Ohio) with a 1 MW, high-voltage, hybrid-electric system at a simulated altitude of 45.000 feet. And that’s important because these systems behave differently at high altitudes. GE’s hybrid-electric system reaches new height.

GE Aviation has been working on the system for some time. It includes an electric motor and generator, power converters, a power transmission, and power control systems. Once fully developed, they will find their way into future hybrid-electric engines. One application will be the RISE open rotor demonstrator program that GE Aviation and Safran announced in June 2021 and that will be run under the CFM name.

The successful tests at 45.000 feet are “an important building block”, said Mohamed Ali, Vice President and General Manager of engineering of GE Aerospace (in the center of the picture, with on the left Tim McCartney of NASA and Boeing’s Brian Yutko on the right). The reason is that these systems behave very differently at altitudes over 10.000 feet. It’s not that they change instantly like clicking a switch.

“What happens above 10.000 feet at high voltage is that you are susceptible to plasma arching. You need to invent the technology to prevent that. That’s not just for the cables, the motor generators also need insulation and how you deal with power conversion as well as with thermal management. This also becomes really important, temperatures variate when you are at different altitudes, thermal management becomes really critical then. We are actually working with Boeing because they have quite a lot of experience in that area with the 787.”

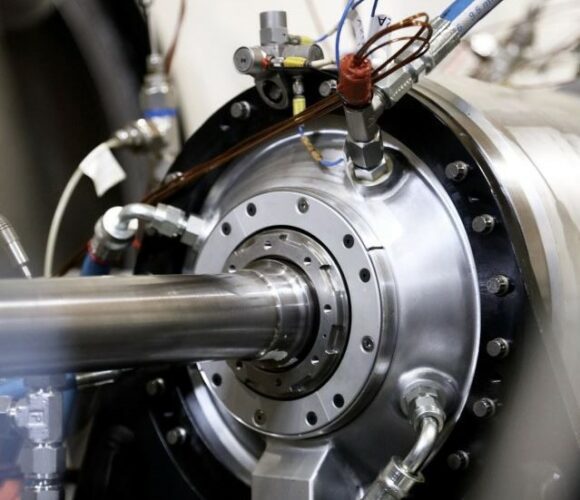

Close-up of the hybrid-electric system that has been tested by GE. (GE Aerospace)

What defines success, Ali was asked at a media conference. “Moving a megawatt or more from a generator to a motor across a long-enough cable, be able to pass and flip that back then. Think about the shared power between the different sides of the aircraft, but also share the power level inside the engines with different spools. So we were able to share that power, moving back and forth, quite reliably and we were able to go all the way from ground take-off conditions to cruise altitudes to 45.000 feet. And the system acted exactly as intended, reliably, with no adverse conditions that we saw. And we did that many times.”

Hydrogen is also on the radar

The hybrid system gets its electricity from batteries, but Ali says that hydrogen is definitely on the radar. “Absolutely. There are concepts that have batteries or fuel cells with hydrogen. That’s why I say there are multiple building blocks with all sorts of technologies that would enable us to provide systems for all kinds of users and customers. (…) Now that you have the power from propulsion, you might as well also integrate it with the aircraft and pass that power between the propulsion system and the aircraft. I mentioned the fuel cell, but it doesn’t have to be that and even without the battery. Some of the concepts that we are looking at are hybrid-electric without battery, no fuel cell, and no hydrogen because you are sharing the load between different spools in a gas turbine engine. That also provides better efficiency.” Ali added: “There are several others that we are maturing between now and the middle of the decade. There is quite some maturation to come, so stay tuned.”

Boeing actively involved

Boeing will be actively involved in the hybrid-electric project. Through its subsidiary Aurora Flight Sciences, it will offer a converted Saab 340B turboprop for doing flight tests later this decade. The hybrid system will be fitted to a General Electric CT7 turboprop engine, as part of the Electrified Powertrain Flight Demonstration (EPFD) program that GE runs together with NASA.

“From the aircraft OEM standpoint, it is interesting to know these systems integrate into aircraft, how they are controlled at an aircraft level as they are now different just from a propulsion to flightdeck standpoint. We have to think about new ways to control systems. That’s why we are doing this aircraft integration as part of our flight test program with NASA. Once they have been proven, they can be used for any future aircraft concepts”, said Brian Yutko, Boeing chief engineer and vice president of Sustainability and Future Mobility.

Before that, certification by the regulators will take some time and effort. “We are finding out now how to do that and how to integrate that”, said NASA’s director of Aeronautics, Tim McCartney.

The RISE open rotor will be positioned on the Airbus A380 flying testbed in a few years from now. (Airbus)

RISE tested on an A380

The hybrid-electric system will definitely find its way into the RISE demonstrator program. “RISE is a hybrid-electric concept. The capability is to actually share the load between the different spools and integrate that. There is also an option to integrate that with the aircraft power system. That’s generally how the concept will be”, said Mohamed Ali.

In a separate media announcement, Airbus and CFM announced on Wednesday that the RISE will be flight tested on Airbus A380 testbed MSN001 in the second half of the decade. The open rotor will be positioned on the engine #2 mounting. RISE will become the second disruptive technology test application on MSN001, as from 2026, it will also be used for testing hydrogen on a GE Passport engine.

Views: 5