The aviation industry hasn’t seen commercial supersonic transportation since the Concorde, that entered service in the 1970s. One of the major factors in that equation is the lack of a fuel-efficient and reliable engine to support supersonic flight. GE just introduced a new engine, the Affinity, for the Aerion AS2 supersonic business jet as the first new supersonic engine in more than 55 years.

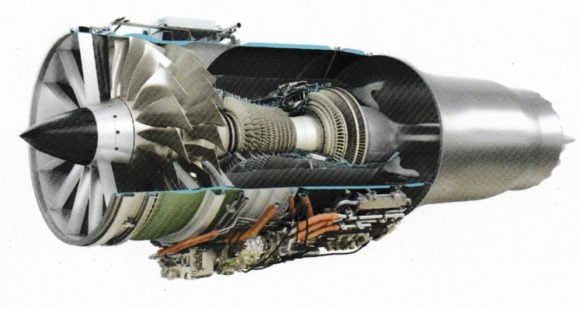

The Affinity is a twin-shaft, twin-fan turbofan that is designed specifically for supersonic applications. It will have the highest bypass ration of any supersonic engine, and is a medium bypass engine, not a turbojet and not like the engines that were on Concorde. The engine will have a two-stage fan, a nine-stage HP compressor (based on the CFM-56), a single stage HP turbine and a two-stage low-pressure turbine with titanium blisks. To reduce the cross-sectional area, the engine is contained in a slimline carbon-fiber casing.

It is the first supersonic engine designed to meet Stage 5 noise requirements and will have a special, non-augmented supersonic exhaust system. GE plans to utilize additive design and manufacturing technologies to optimize the weight and performance of the engine, as it has done with the next generation Catalyst turboprop. The engine will incorporate a Full Authority Digital Engine Control and will be optimized for supersonic flight over water as well as efficient sub-sonic flight over land.

Brad Mottier, President and General Manager for Business and General Aviation and Integrated Services at GE Aviation, said that “in the last 50 years, business aircraft speeds have increased by less than 10%. Instead of going faster, cabins have increased in size and become more comfortable – and range has become longer. With large, comfortable cabin long-range aircraft in the marketplace, the next step is speed.”

The Affinity blends technologies from a number of GE engine programs, including those from its commercial CFM-56 engine family, design features and lessons learned from military engine programs, and features including the front fan blisks and slimline composite core ducting from the GE Passport business aircraft engine. Thrust for the Affinity family will range from 16,000 to 20,000 pounds per engine.

Design requirements for a modern supersonic commercial engine include super-cruise capability (sustained supersonic flight without afterburners), noise compliance, and high reliability. The Affinity has been designed to deliver on each of those requirements. With durable “hot and harsh” combustors and advanced coatings for the turbine section, the Affinity is optimized for sustained supercruise. It’s slim, low-bypass design is ideal for high altitude operations and a service ceiling of 60,000 feet.

Acoustic treatments are utilized throughout the engine to ensure that the Affinity engine meets or exceeds regulatory requirements for noise. With much of the HP core based on the CFM-56, the engine design has been optimized for reliability and high-speed, high-altitude operations.

The Bottom Line:

Getting from point A to point B quickly is the reason we fly, and since Concorde, maximum speeds have fallen. A new family of engines optimized for supersonic flight will provide new opportunities for supersonic business jets, with Aerion the first announced application for the new engine. We welcome the return of speed to business aviation!

Views: 32