Reports this weekend indicate that GE may merge its aircraft leasing unit with AerCap, as GE continues its corporate...

GE Aircraft Engines

On January 13 Airbus announced that its teams created the first-ever single-piece composite center wing box. This represents an...

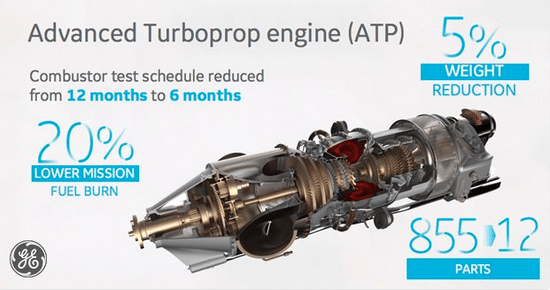

It is nothing short of eye popping: 855 parts reduced to 12? GE’s ATP is going to be an...

Norman Baker is President & Managing Executive of GE’s Business & General Aviation Turboprop business. He explains why GE...

GE has been at the forefront of additive manufacturing for a while. Though not alone in seeing the benfits...

GE Aviation reported it has completed initial ground testing of the first full GE9X development engine, the world’s largest...